The current market for water heating solutions has seen a growing demand for efficient, safe, and environmentally friendlyoptions. This document proposes the introduction of an automatic natural gas geyser system that operates without a pilot light. By utilizing electronic sensors and ignition mechanisms, this innovative product can effectively function even in low natural gas pressure environments. This advancement aims to address consumer concerns related to safety, energyefficiency, and adaptability to varying gas pressure conditions

Problem Statement:

- Social Hazard: Natural gas shutdown is common it creates serious health and emotional hazard to turn on the natural gas geezer or to check time by time for the availability of natural gas

- Safety Concerns: Traditional gas geysers with pilot lights pose safety risks such as gas leaks and unintended

ignition.

- Energy Inefficiency: Pilot lights contribute to unnecessary gas consumption, leading to higher operational costs and environmental impact.

- Inconsistent Performance: Existing gas geysers struggle to maintain functionality in areas with low natural gas pressure, resulting in unreliable performance.

Solution

Avanzio Technologies has developed an automatic natural gas geyser equipped with electronic sensors and ignition systems that eliminate the need for a pilot light. This product is designed to:

1. Ensure enhanced safety through advanced monitoring and shut-off mechanisms.

2. Improve energy efficiency by eliminating wasteful gas consumption associated with pilot lights.

3. Operate efficiently in low natural gas pressure environments, ensuring consistent performance and user satisfaction

4. Growing Demand for Energy-Efficient Solutions: Consumers are increasingly seeking energy-efficient appliances

that reduce operational costs and environmental impact.

5. Safety-Conscious Consumers: The market includes a significant segment of consumers who prioritize safety features in household appliances.

6. Diverse Geographic Needs: Areas with inconsistent or low natural gas pressure present a unique market opportunity for a geyser designed to operate under such conditions

A special microcontroller system has been designed to control and read temperature to Ignite or shut off the designed burner. The controller also provides two-layer safety control system

Solenoid valve controlled by the microcontroller chip that monitor gas flow, and electrically energized or de-energized, either shut off or allow gas flow

A reliable electronic ignition system will replace the traditional pilot light, improving efficiency and safety

Innovative burner has been designed that features the geyser to operate efficiently even in low natural gas pressure environments

The product will feature an intuitive interface for easy operation and monitoring of performance metrics.The user interface includes an LCD to display water temperature and two push buttons to control the desired temperature of the unit

The new burner produces blue flame instead of conventional yellow flame which result is more than 90% of natural gas burring and produced low carbon emissions

The product is designed to operate on 12DC ~ 2-5amp adapter on conventional USB-C type port for the convenience

The whole units are designed and assembled in conventionally used geyser hood which can be installed within 5-10 minutes by removing old traditional system without any alteration.

The overall system is maintains free and all parts of the units are readily available in the local market except burner and microcontroller which is the sole proprietor of Avanzino Technologies innovative research

By keeping the local user purchasing power capacity the product has been designed on manual and can be transferred to IOT by simply plug-in the IOT module in case of user demand.

Ensuring compliance with industry standards and regulations related to gas appliances

is crucial to mitigate legal and safety risks.

Natural Gas Saving

Estimating the amount of natural gas saved by a water geyser that operates without a pilot light involves several factors,

including the efficiency of the geyser, frequency of usage, local gas prices, and specific consumption rates. Here’s a simplified approach to calculating potential savings:

The number of hours the geyser operates daily and the number of days it is used in a month will impact the total gas consumption.

Modern gas geysers are generally more efficient than older models. However, the

specific efficiency rating (e.g., Energy Factor or Thermal Efficiency) will influence the amount of gas saved

The cost of natural gas per unit (e.g., cubic feet or therms) varies by location and can impact the financial savings associated with reduced consumption

Financial Impact

20Millioin USD is the direct saving yearly which is about PKR 5 Billion on current market rate

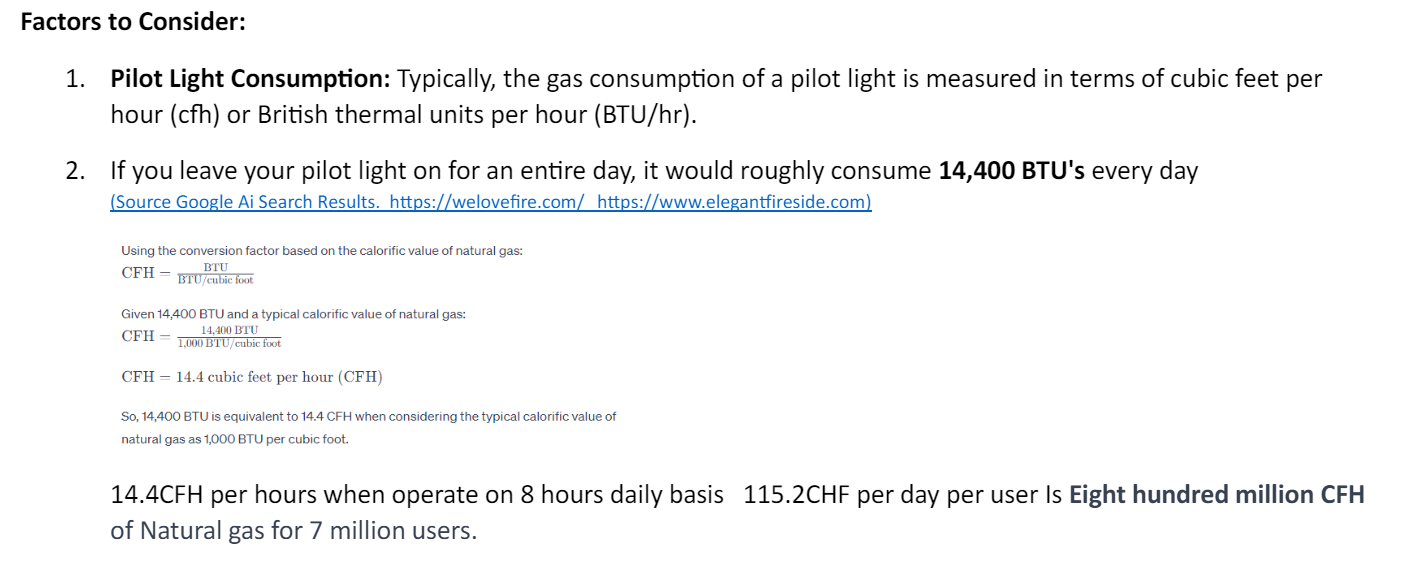

Pilot Light Consumption: Traditional geyser pilot light consumes 14,400 BTUs/Day. = 0.0144MMBTU

2. Geyser operates 8 hours/day for 30 days (240 hours/month).

3. Number of Users: There are 7 million users.

4. Total monthly consumption of traditional geyser: 0.0144MMBTU/hour × 8 hours=0.1152MMBTU = 3.456 MMBTUs Monthly

5. Natural Gas saving 3.456MMBTU x 7,000,000Users = 2,419,200MMBTU

6. Currently GAS price is approx. on protected category is 200PKR/MMBTU ($0.72USD)

7. The cost saving of 2,419,200 MMBTU when the gas price is $0.72 per MMBTU would be $1,741,184.

8. Monthly/ Yearly Saving: Monthly $1,741,184 is $20,894,208USD Yearly

Environmental Effect

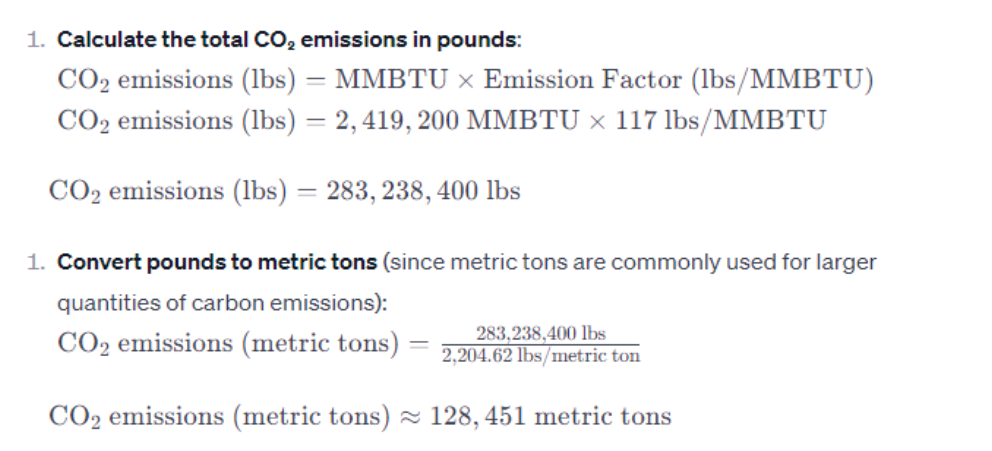

To determine the amount of carbon emissions eliminated by avoiding the consumption of Eight Hundred Million CFH or 2,419,200MMBTU of natural gas, we first need to calculate the carbon emissions associated with burning this amount of natural gas. The carbon emissions from burning natural gas can be estimated based on the carbon intensity of natural gas and standard conversion factors

Carbon Intensity of Natural Gas: The carbon intensity of natural gas can vary based on its composition, but a common average value is approximately 117 pounds of CO2 per MMBTU (million British thermal units) of natural gas burned.

Therefore, when 2,419,200 MMBTU of natural gas is burned in geyser pilots, approximately 283,238,400 pounds or about 128,451 metric tons of carbon dioxide (CO₂) emissions would be produced, based on the given emission factor.

Conclusion:

The actual conversion of carbon emissions into carbon credits requires consideration of specific market conditions,regulatory frameworks, verification processes, and other factors relevant to the particular carbon trading or offsetting programs involved. Consulting with experts in the field or relevant organizations specializing in carbon markets and environmental credits would provide more accurate and tailored guidance based on current standards and practices